In today’s fast-paced electronics industry, finding a reliable and affordable PCB prototype supplier is crucial for bringing innovative products to market quickly and cost-effectively. As JHYPCB, a leading PCB manufacturer in China, we understand the challenges engineers and product developers face when seeking high-quality, budget-friendly PCB prototyping solutions. This comprehensive guide will walk you through the key criteria for selecting the ideal cheap PCB prototype supplier, ensuring that you get the best value for your investment without compromising on quality.

Define your requirements for the cheap PCB prototype

When embarking on a journey to find the best cheap PCB prototype supplier, the first and most crucial step is to clearly define your requirements. A well-defined set of specifications not only helps you communicate effectively with potential manufacturers but also ensures that you receive accurate quotes and ultimately, a product that meets your expectations.

Why Defining Requirements is Critical

- Accurate Quotes: Detailed specifications allow manufacturers to provide precise cost estimates, avoiding unexpected charges later.

- Quality Assurance: Clear requirements help ensure that the final product meets your exact needs and quality standards.

- Time Efficiency: Well-defined specs reduce back-and-forth communication and potential misunderstandings, speeding up the prototyping process.

- Comparison Shopping: With standardized requirements, you can easily compare offerings from different suppliers.

Key Aspects to Consider

When defining your PCB prototype requirements, consider the following aspects:

1. Board Specifications

- Number of Layers: Specify whether you need a simple double-sided board or a complex multilayer PCB.

- Board Size: Provide exact dimensions (length, width, and thickness).

- Material: Indicate the preferred board material (e.g., FR-4, Rogers, Polyimide for flex PCBs).

- Copper Weight: Specify the copper thickness (e.g., 1 oz, 2 oz).

2. Design Complexity

- Minimum Trace Width and Spacing: Define the smallest trace width and spacing between traces your design requires.

- Hole Sizes: Specify the smallest hole size and whether you need micro vias or buried/blind vias.

- Aspect Ratio: For high-density designs, specify the required aspect ratio for holes.

3. Special Requirements

- Impedance Control: If needed, specify the required impedance values and tolerances.

- Surface Finish: Indicate your preferred surface finish (e.g., HASL, ENIG, Immersion Silver).

- Solder Mask and Silkscreen: Specify colors and any special requirements.

4. Production Details

- Quantity: Clearly state the number of prototypes needed.

- Turnaround Time: Specify your required lead time.

- Panelization: If applicable, provide panel specifications or indicate if you need the manufacturer’s recommendation.

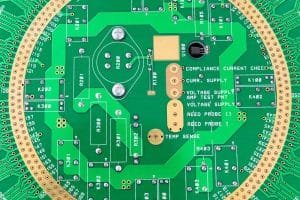

5. Testing and Quality Assurance

- Electrical Testing: Specify if you require 100% electrical testing, flying probe tests, etc.

- Inspection Criteria: Define acceptable quality levels (AQLs) for various defects.

- Special Testing: Indicate any specific tests required (e.g., impedance testing, solderability tests).

6. Documentation and Files

- Design Files: Specify the format of your design files (e.g., Gerber, ODB++).

- Additional Documentation: Indicate if you’ll provide assembly drawings, BOM, or other supporting documents.

Tips for Effective Requirement Definition

- Be Specific: The more detailed your requirements, the less room for misinterpretation.

- Prioritize: Clearly indicate which specifications are critical and which have some flexibility.

- Consider Future Needs: If you anticipate moving to production, mention this to ensure the prototype process aligns with future manufacturing.

- Seek Expert Input: If uncertain about any aspects, consult with PCB design experts or potential manufacturers for guidance.

- Document Everything: Keep a detailed record of your requirements for future reference and iterations.

By thoroughly defining your requirements for cheap PCB prototypes, you set the stage for a successful partnership with your chosen manufacturer. This detailed approach ensures that you receive high-quality, cost-effective prototypes that precisely match your project needs.

Evaluate Engineering Expertise

When searching for an affordable PCB prototype supplier, one of the most critical factors to consider is their engineering expertise. The depth and breadth of a manufacturer’s technical knowledge can significantly impact the quality, reliability, and cost-effectiveness of your prototypes. At JHYPCB, we pride ourselves on our cutting-edge engineering capabilities, which enable us to deliver superior cheap PCB prototypes consistently. Here’s what you should look for when evaluating a supplier’s engineering prowess:

Proficiency in Advanced PCB Design Tools

A top-tier PCB prototype supplier should demonstrate mastery of industry-standard design software. Look for expertise in:

- Altium Designer: Known for its powerful 3D visualization capabilities and integrated library management.

- Cadence Allegro: Favored for complex, high-speed designs and signal integrity analysis.

- Mentor PADS: Offers robust thermal management features and support for flex and rigid-flex designs.

- Eagle PCB: Popular for its user-friendly interface and extensive component libraries.

At JHYPCB, our engineers are proficient in all these platforms, ensuring seamless collaboration regardless of your preferred design environment.

Strong Design for Manufacturing (DFM) Knowledge

DFM expertise is essential for ensuring that your prototype can be manufactured efficiently and cost-effectively. A supplier with strong DFM knowledge will:

- Optimize designs for manufacturability without compromising performance

- Identify potential issues early in the design process

- Suggest improvements to enhance yield and reduce costs

- Ensure compliance with industry standards (IPC, JEDEC, etc.)

JHYPCB’s engineering team conducts thorough DFM reviews on all prototype orders, often saving our clients time and money by catching issues before production begins.

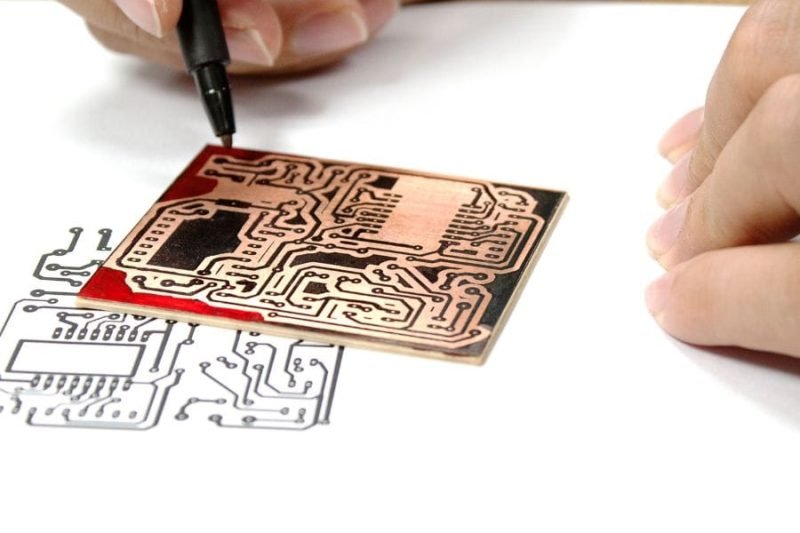

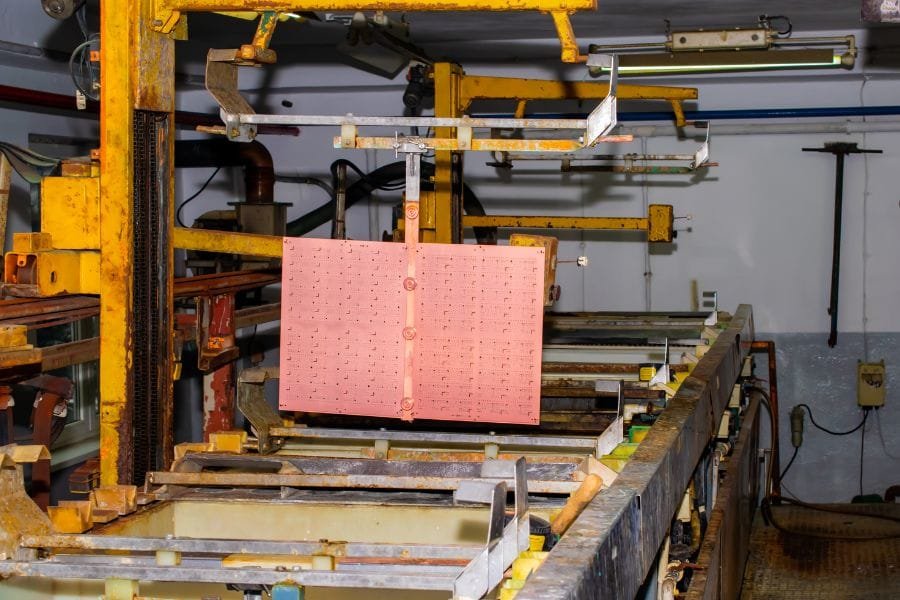

State-of-the-Art Manufacturing Equipment

The quality of PCB prototypes is directly related to the manufacturing equipment used. A reputable supplier should invest in advanced machinery for:

- High-precision drilling and routing

- Fine-line etching and plating

- Automated optical inspection (AOI)

- Flying probe and in-circuit testing

- X-ray inspection for hidden solder joints

At JHYPCB, we continually upgrade our equipment to stay at the forefront of PCB manufacturing technology, ensuring that even our cheap PCB prototypes benefit from the latest advancements in the industry.

Rigorous Quality Control Processes

Look for a supplier with comprehensive quality control measures, including:

- Incoming material inspection

- In-process quality checks

- Final electrical testing

- Dimensional and visual inspections

- Solderability testing

- Environmental stress screening (when required)

JHYPCB’s ISO 9001-certified quality management system ensures that every prototype undergoes rigorous testing before shipment, maintaining our reputation for reliability and excellence.

Relevant Industry Certifications

Certifications serve as a testament to a supplier’s commitment to quality and industry best practices. Key certifications to look for include:

- ISO 9001: Quality management systems

- IPC-A-600: Acceptability of printed boards

- UL Certification: Safety standards compliance

- ISO 14001: Environmental management systems

- AS9100: Quality management for aerospace industry (if applicable)

JHYPCB holds all these certifications and more, demonstrating our dedication to meeting and exceeding industry standards across various sectors.

By thoroughly evaluating these aspects of engineering expertise, you can ensure that your chosen cheap PCB prototype supplier has the necessary skills and resources to bring your designs to life accurately and cost-effectively. At JHYPCB, we combine advanced technical capabilities with affordable pricing, offering you the best of both worlds in PCB prototyping.

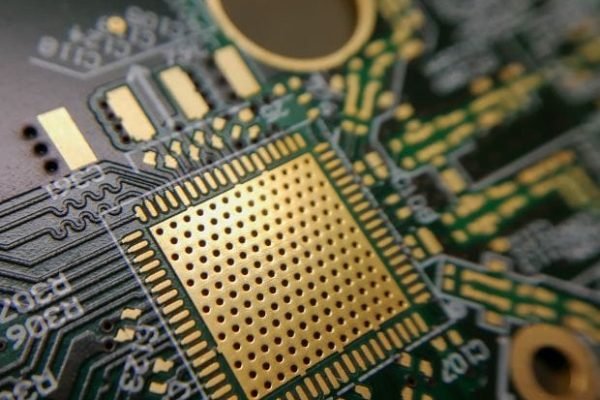

Experience with Complex Layouts and High-Speed Signal Routing

As electronic devices become increasingly sophisticated, the ability to handle complex PCB layouts is crucial. Your chosen supplier should have proven experience in:

- High-layer count boards (8 layers and above)

- Fine-pitch component placement

- Controlled impedance routing

- High-speed digital designs (DDR4, PCIe, USB 3.0+)

- RF and microwave circuit layouts

Our team at JHYPCB has successfully produced cheap PCB prototypes for cutting-edge applications, including 5G infrastructure, IoT devices, and advanced medical equipment.

Evaluating Production Capabilities for Rapid, Scalable Affordable PCB Prototyping

When searching for the ideal cheap PCB prototype supplier, assessing their production capabilities is crucial. You need a partner who can not only deliver high-quality prototypes quickly but also offer the flexibility to scale up as your project evolves. This section will guide you through the key factors to consider when evaluating a manufacturer’s production capabilities for affordable PCB prototyping.

Quick-Turn Capabilities

In the fast-paced world of electronics development, time is often of the essence. Look for suppliers offering:

- 24-48 Hour Turnaround: For urgent projects, some manufacturers offer super-fast turnaround times.

- Standard Quick-Turn Options: Most quality suppliers should offer 3-5 day turnaround for standard orders.

- Flexible Scheduling: The ability to expedite orders when needed without excessive premium charges.

Tip: Ask about their track record for on-time delivery and any guarantees they offer for meeting promised deadlines.

Low Volume Production

Affordable PCB prototyping often involves small batch sizes. Evaluate suppliers based on:

- Minimum Order Quantities (MOQ): Look for suppliers willing to produce as few as 5-10 boards without significant price increases.

- Price Breaks: Understand at what quantities price breaks occur to plan your ordering strategy.

- Setup Fees: Check if there are any setup fees for small orders and how these compare across suppliers.

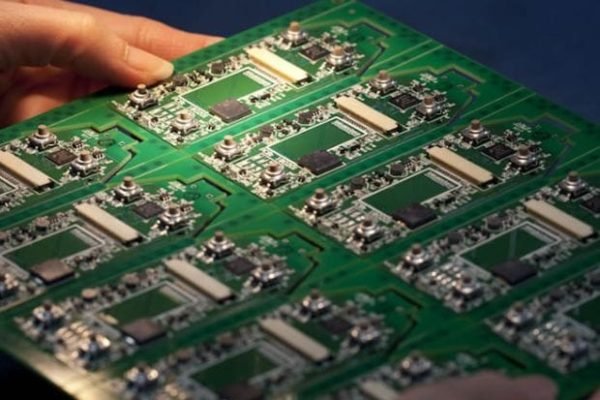

High-Mix, Low-Volume Capabilities

Many prototyping projects involve multiple design iterations or various board types. Assess the supplier’s ability to handle:

- Diverse Board Types: Can they efficiently produce different PCB types (e.g., rigid, flex, rigid-flex) in the same order?

- Quick Changeovers: How efficiently can they switch between different product runs?

- Design Revisions: How do they handle frequent design changes or multiple versions of a prototype?

Scalability

As your project progresses, you may need to increase production volumes. Consider:

- Capacity Range: Can the supplier handle both small prototype runs and larger production volumes?

- Scaling Costs: How do their prices scale with volume? Are there significant economies of scale?

- Production Transition: How smooth is their process for transitioning from prototype to low or high-volume production?

Manufacturing Equipment and Technology

The quality and capabilities of a supplier’s equipment directly impact their ability to produce affordable, high-quality prototypes. Inquire about:

- Equipment List: What types of machines do they use for PCB fabrication and assembly?

- Technology Capabilities: Can they handle advanced technologies like HDI, micro vias, or specialized materials?

- Recent Investments: Have they recently upgraded their equipment or plan to do so in the near future?

Production Monitoring and Quality Control

Ensure the supplier has robust systems for monitoring production and maintaining quality:

- Real-Time Tracking: Do they offer real-time order tracking and production status updates?

- In-Process Quality Checks: What quality control measures do they have throughout the production process?

- Final Inspection: What methods do they use for final product inspection (e.g., AOI, X-ray for complex boards)?

Prototyping-Specific Services

Look for additional services that can enhance your prototyping experience:

- Design for Manufacturability (DFM) Check: Do they offer free DFM checks to catch potential issues before production?

- Assembly Services: Can they handle PCB assembly for your prototypes, including sourcing components?

- Testing Services: What types of electrical and functional testing do they offer for prototypes?

Flexibility and Communication

Prototyping often requires agility and clear communication. Assess:

- Responsiveness: How quickly do they respond to queries or requests for changes?

- Technical Support: Do they offer expert technical support throughout the prototyping process?

- Customization: Are they willing to accommodate special requests or unique requirements?

When evaluating production capabilities for affordable PCB prototyping, look for a supplier that offers a balance of speed, flexibility, quality, and scalability. The ideal partner should be able to handle your immediate prototyping needs efficiently while also having the capacity to support your project as it grows.

Remember, at JHYPCB, we pride ourselves on offering all these capabilities and more. Our state-of-the-art facilities, experienced team, and customer-centric approach make us an excellent choice for all your cheap PCB prototype needs, from simple designs to complex, multi-layer boards.

Comparing Pricing Models for Affordable PCB Prototype Solutions

When searching for the best cheap PCB prototype supplier, understanding and comparing pricing models is crucial. A transparent and fair pricing structure not only ensures you get the best value for your money but also helps avoid unexpected costs down the line. At JHYPCB, we believe in providing clear, competitive pricing that reflects the true cost of producing high-quality PCB prototypes. Here’s what to look for when evaluating pricing models:

Transparent, Component-Level Quotations

A reputable PCB prototype supplier should provide detailed, itemized quotes that break down costs at the component level. This transparency allows you to:

- Understand exactly what you’re paying for

- Identify areas where costs can potentially be reduced

- Compare quotes from different suppliers more accurately

At JHYPCB, we provide comprehensive quotes that detail costs for materials, labor, testing, and any special processes required for your prototype.

Clear Cost Drivers

Look for suppliers who clearly explain the factors that influence the cost of your PCB prototype. Common cost drivers include:

- Board size and shape

- Number of layers

- Material type (e.g., FR-4, Rogers, flex)

- Copper weight

- Minimum trace width and spacing

- Number and type of holes (through-holes, blind vias, buried vias)

- Surface finish (e.g., HASL, ENIG)

- Solder mask and silkscreen colors

- Testing requirements

Understanding these factors can help you make informed decisions about your design that could potentially reduce costs without compromising quality.

Non-Recurring Engineering (NRE) Fees

NRE fees are one-time costs associated with setting up the manufacturing process for your specific prototype. When comparing suppliers:

- Check if NRE fees are clearly stated

- Understand what’s included in these fees

- Look for suppliers who offer reduced or waived NRE fees for repeat orders

At JHYPCB, we strive to keep NRE fees to a minimum and often waive them entirely for returning customers or larger orders.

Volume-Based Discounts

Even for prototype orders, some suppliers offer discounts based on quantity. A good pricing model should:

- Clearly show how prices decrease as order quantity increases

- Offer reasonable price breaks, even for small increases in quantity

- Provide options for ordering extra pieces at a reduced rate

We at JHYPCB offer competitive volume-based discounts starting from very low quantities, making it economical to order a few extra prototypes for testing or backup.

No Hidden Charges

Beware of suppliers who offer attractively low base prices but then add numerous additional charges. Look for pricing models that:

- Include all standard processes in the base price

- Clearly state any potential additional charges upfront

- Offer a final, all-inclusive price with no surprises

JHYPCB prides itself on our no-hidden-charges policy, ensuring that the price we quote is the price you pay.

Flexible Payment Terms

Consider suppliers who offer flexible payment options, especially for larger orders or repeat customers. Look for:

- Multiple payment method options

- Potential for net payment terms for established clients

- No additional fees for standard payment methods

We offer a range of payment options at JHYPCB and are always willing to discuss terms that work best for our clients’ needs.

Prototyping Package Deals

Some suppliers offer special pricing packages for prototyping services. These might include:

- Bundled pricing for multiple design iterations

- Combined pricing for PCB fabrication and assembly

- Discounts for ordering prototypes along with production quantities

JHYPCB offers several cost-effective prototyping packages designed to support the entire product development cycle, from initial concept to final production.

Cost of Expedited Services

If you frequently need quick-turn prototypes, pay close attention to the pricing for expedited services. Compare:

- Rush order fees

- Guaranteed delivery times for various service levels

- Any limitations on design complexity for expedited orders

At JHYPCB, we offer competitive pricing for our quick-turn and rapid PCB prototyping services, ensuring you can get high-quality prototypes fast without breaking the bank.

By carefully evaluating these aspects of a supplier’s pricing model, you can ensure you’re getting the best value for your cheap PCB prototype needs. At JHYPCB, we strive to offer the most competitive pricing without compromising on quality or service. Our transparent pricing model, combined with our technical expertise and state-of-the-art manufacturing capabilities, makes us an ideal partner for all your PCB prototyping needs.

Verifying Specialized Technical Expertise for Advanced Affordable Prototypes

HDI technology is essential for miniaturization and improved signal integrity. Verify that your supplier can handle:

- Microvias and buried/blind vias

- Ultra-fine line width and spacing (3 mil or less)

- Stacked and staggered vias

- Advanced materials compatible with HDI (e.g., low-loss laminates)

JHYPCB Advantage: Our state-of-the-art equipment allows us to produce HDI boards with up to 16 layers and line width/spacing as low as 2 mil, ensuring we can meet the most demanding HDI requirements.

RF/Microwave PCBs

For high-frequency applications, specialized knowledge is critical. Look for expertise in:

- Impedance control and matching

- Stripline and microstrip design

- Use of specialized RF materials (e.g., Rogers, Taconic)

- Controlled dielectric constant and loss tangent

- Copper surface roughness management

JHYPCB Advantage: We have extensive experience in RF/Microwave PCB fabrication, including precise impedance control (±5% tolerance) and the ability to work with a wide range of high-frequency materials.

Flexible and Rigid-Flex Circuits

Flex and rigid-flex PCBs require unique manufacturing processes. Ensure your supplier can handle:

- Various flex materials (e.g., Polyimide, LCP)

- Dynamic flex applications

- Rigid-flex transitions

- Controlled impedance on flex circuits

- Specialized surface finishes for flex circuits

JHYPCB Advantage: Our flex and rigid-flex capabilities include up to 8 layers, with expertise in both single and double-sided flex circuits, as well as complex rigid-flex designs.

High-Temperature and Thermal Management PCBs

For applications in harsh environments or with high heat dissipation, look for:

- Experience with high-Tg and halogen-free materials

- Thermal management techniques (e.g., heavy copper, coin technology)

- IMS (Insulated Metal Substrate) PCB capabilities

- Knowledge of thermal simulation and analysis

JHYPCB Advantage: We offer a range of thermal management solutions, including heavy copper (up to 12 oz), coin technology, and IMS PCBs with excellent thermal performance.

Advanced Packaging and Embedded Components

For cutting-edge miniaturization, verify capabilities in:

- Embedded passive and active components

- Chip-on-board (COB) technology

- Advanced IC packaging support (e.g., BGA, CSP, QFN)

- 3D packaging solutions

JHYPCB Advantage: Our advanced packaging capabilities include embedded components, COB technology, and support for a wide range of advanced IC packages.

High-Speed Digital Designs

For high-speed applications, ensure expertise in:

- Controlled impedance routing (differential pairs)

- Signal integrity analysis and optimization

- Backplane design and fabrication

- Support for high-speed protocols (e.g., PCIe, USB 3.0+, DDR4/5)

JHYPCB Advantage: We have extensive experience in high-speed digital designs, offering precise impedance control and signal integrity optimization for boards operating at frequencies up to 100 GHz.

Special Materials and Processes

Look for experience with:

- Exotic materials (e.g., Teflon, ceramic PCBs)

- Special plating processes (e.g., selective hard gold, silver plating)

- Conformal coating application

- Hybrid PCB constructions

JHYPCB Advantage: Our capabilities extend to a wide range of special materials and processes, allowing us to meet unique project requirements.

Prototyping for Specific Industries

Different industries have unique requirements. Verify expertise in your specific sector, such as:

- Aerospace and Defense (AS9100 certification)

- Medical devices (ISO 13485 certification)

- Automotive (IATF 16949 certification)

- Industrial IoT and Industry 4.0 applications

JHYPCB Advantage: We hold multiple industry-specific certifications and have experience across various sectors, ensuring we can meet specialized regulatory and performance requirements.

How to Verify Specialized Expertise

When evaluating a cheap PCB prototype supplier’s specialized technical expertise:

- Request case studies or examples of similar projects they’ve completed.

- Ask for technical capabilities documents detailing their equipment and processes.

- Inquire about their engineering team’s qualifications and experience.

- Check for relevant certifications specific to your industry or technology needs.

- Request a sample or prototype to evaluate their capabilities firsthand.

At JHYPCB, we’re always ready to demonstrate our specialized technical expertise. Whether you need quick-turn prototypes for a cutting-edge IoT device or complex, high-reliability PCBs for aerospace applications, our team has the knowledge and capabilities to bring your designs to life efficiently and cost-effectively.

By thoroughly vetting a supplier’s specialized technical expertise, you ensure that your cheap PCB prototypes will be produced with the highest level of precision and quality, regardless of their complexity or unique requirements.

Evaluating Expertise Across the Full Spectrum of Affordable PCB Prototypes

A qualified affordable PCB prototype supplier should demonstrate proven capabilities in manufacturing the entire range of printed circuit board designs cost-effectively – from simple double-sided boards to highly complex builds.

For basic affordable PCB prototypes like double-sided or 4-layer boards, assess their skills in achieving tight tolerances, minimum feature sizes, and reliably assembling components like SMT, QFPs, connectors, and other common devices. Design for manufacturability is key for these simpler builds.

However, it’s equally important to validate their expertise with complex and advanced affordable prototyping projects. This includes multilayer boards, HDI technologies, flexible and rigid-flex circuit builds, and other sophisticated designs. These often require specialized know-how in advanced processes like high-aspect ratio via formation, sequential lamination, controlled impedance routing, and more.

Review real examples where they’ve successfully produced affordable prototypes featuring high-density BGA packages, ultra-fine 01005 passives, multi-row QFNs, and other leading-edge component integrations. Demonstrated experience with cutting-edge miniaturization techniques like laser vias and embedded components is also highly valuable.

An ideal affordable prototyping partner should provide evidence of their breadth across the full spectrum – from basic builds to complex HDI and rigid-flex boards. This comprehensive perspective allows you to objectively assess their overall technical capabilities for delivering exceptional quality on your specific affordable PCB prototype requirements.

Requesting References and Sample Boards from Prior Affordable Prototyping Projects

When evaluating affordable PCB prototype suppliers, requesting references and samples of their previous work can provide invaluable insights into their actual capabilities. This first-hand evidence allows you to validate claims about quality, expertise and service levels objectively.

Ask potential vendors to share physical examples of affordable prototypes they’ve manufactured, especially for products similar to your target application. Reviewing real sample boards gives you a tangible sense of their build quality, workmanship and attention to detail.

Additionally, request referrals and contact information for past customers with projects comparable in complexity and requirements to yours. Follow up with those references to gain direct feedback on the prototype partner’s technical expertise, responsiveness, adherence to budgets/timelines and overall customer experience.

Suppliers who readily provide reference contacts and showcase a diverse portfolio of prior affordable PCB prototyping projects across industries demonstrate transparency and confidence in their skills. Testing sample boards yourself and speaking candidly with previous clients offers perhaps the most reliable assessment of whether a vendor is the right fit for your needs.

Conclusion

Finding the ideal partner for affordable yet high-quality PCB prototypes is pivotal to cost-effectively bringing your product designs to market. Carefully evaluating suppliers based on engineering proficiency, rapid PCB prototyping capabilities, transparent pricing models, technical specializations and proven experience produces well-informed decisions.

While seeking expedited turnarounds and economical pricing, take the time to thoroughly vet vendors against the key criteria outlined. This due diligence helps mitigate risks and avoid potential issues with quality, delays or hidden costs down the line. Selecting an affordable PCB prototyping manufacturer closely aligned with your exact needs lays the critical groundwork for successful product development within budget.