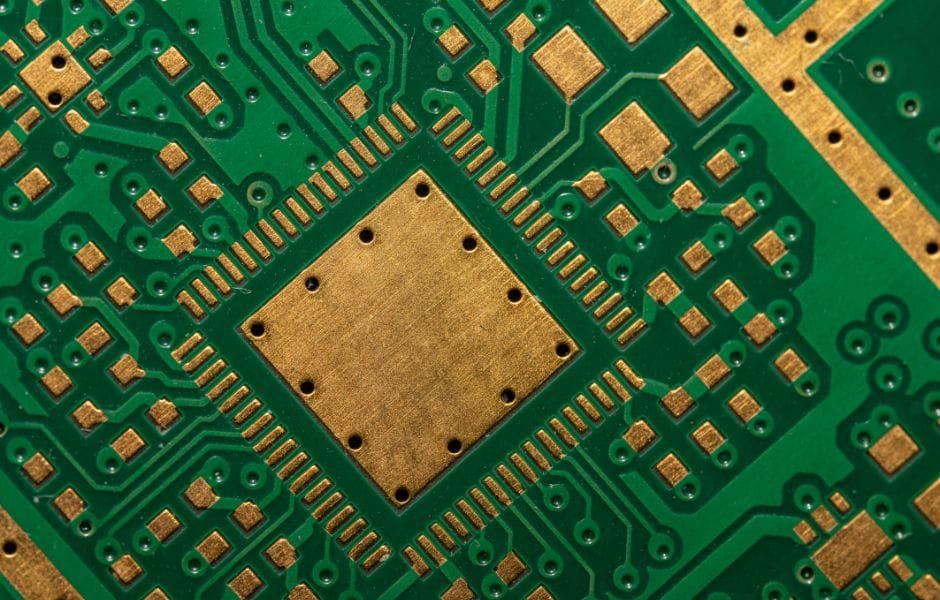

Printed circuit boards are critical in the electronics industry, connecting electrical signals and electronic components. However, producing high-quality PCBs requires strict control over every step in the process, with one important step being the creation of PCB Gerber files. Gerber files are standard CAD files containing information about the different layers of the PCB, allowing manufacturers to produce PCBs that match the design perfectly. The application of Gerber files enables quick identification and correction of any inconsistencies with the original design during quality control and inspection.

I. What Are Gerber Files?

Gerber Files are standard CAD (Computer-Aided Design) files containing information about the different layers of a PCB, including the conductive and non-conductive layers and the drill and mill files. These files are used in the manufacturing process of a PCB to create a physical board that matches the desired design.

1 - History of Gerber Files

Gerber Files were first introduced in the 1960s by the Gerber Scientific Instrument Company to communicate PCB designs between designers and manufacturers. The files were initially created using a photoplotter, which exposed a photographic film to a light source to generate the image of the circuit board.

Over the years, the Gerber File format has evolved to include more information about a PCB’s different layers and components. Today, the format is widely accepted in the industry and is used by most PCB manufacturers and designers.

2 - Applications of Gerber Files

Gerber Files are essential in the PCB manufacturing process as they provide a detailed and accurate description of the board’s design. Manufacturers use these files to create copper traces, solder masks, silkscreens, and other features of the PCB.

Gerber Files have become the standard in the industry and are used by all manufacturers to ensure compatibility between different design software and manufacturing equipment. They are also used for quality control and inspection of the finished product, as any deviations from the original design can be quickly identified and corrected.

In addition, Gerber Files are also used for prototyping and testing, allowing designers to experiment with new designs and quickly produce physical boards for testing and evaluation.

II. Gerber File Format

Gerber files are one of the most common file formats used in PCB manufacturing. They contain all the necessary information needed to manufacture a printed circuit board. Gerber files describe the different layers of a circuit board, such as the signal layer, drill layer, assembly layer, etc. They are typically exported automatically by CAD software and are used by PCB manufacturers as a guide for the manufacturing process.

There are many versions of Gerber files, but most are based on text-based NC code format. Text-formatted Gerber files typically include all the holes and traces on the current image layer and other layers referenced in the file through prefix naming. The format of Gerber files can be very complex, as different vendors and software packages use different formats and parameters to represent the same information. In this chapter, we will delve into the basic structure, coordinate system, layer definition, naming conventions of Gerber files, and the differences and relationships between the common Gerber file formats and versions.

1 - Basic Structure of Gerber Files

Gerber files are ASCII-formatted plain text files, and their basic structure includes:

Header: Includes the manufacturer’s information, the number of layers, the unit type, and the coordinate format.

Drawing: Converts the PCB layout into geometric elements and components.

Apertures: Define the objects of different shapes and sizes for PCB elements.

Interpreter: Translates commands into instructions that PCB manufacturing machines can understand.

Used layers: Divide the PCB into various sections so that machines can manufacture their respective parts.

Gerber files typically include multiple levels, which can be identified with different extensions (e.g., .gbl, .gto, .gts, .gm1). Each layer is defined by a set of independent apertures, including information about holes, line widths, line spacing, and scales so the PCB manufacturing machine can manufacture their respective parts based on the defined specifications.

2 - Coordinate System of Gerber Files

The coordinate system is an important part of the Gerber file structure. It defines the origin, orientation, and units of measurement for the file.

The origin is the point on the PCB where the (0,0) coordinates are located. The coordinate system allows PCB designers to choose the location of the origin and orient the PCB to optimize layout and performance.

In addition to the origin, the coordinate system also defines the spacing between copper traces and the Aperture Template (APT) used to define the shape of the traces. This is important for ensuring that the PCB is manufactured accurately and precisely.

The coordinate system is typically defined in millimeters or inches, although other units can also be used. Using consistent units throughout the Gerber file is important to avoid errors during PCB manufacturing.

3 - Layer Definition in Gerber Files

Layer definition in Gerber files is an important aspect of PCB fabrication. To produce a PCB with the desired functionality, it is necessary to define the different layers that will be present in the design. The Gerber format defines the layers and components that make up the PCB layout.

A Gerber file can define Several different layers, including the top copper layer, bottom copper layer, solder mask layer, silkscreen layer, and drill layer. Each of these layers serves a specific purpose in the PCB fabrication process.

The top copper layer is where most of the circuit traces will be located. This layer is defined in the Gerber file using the .gtl extension. The bottom copper layer is similar to the top copper layer, except on the bottom of the PCB. This layer is defined in the Gerber file using the .gbl extension.

The solder mask layer covers the copper traces, pads, and vias with a polymer layer to prevent the solder from bridging between connections during assembly. This layer is defined in the Gerber file using the .gts extension.

The silkscreen layer defines the text and graphics on the PCB, such as component designators, logos, and board outlines. This layer is defined in the Gerber file using the .gto extension.

Finally, the drill layer is used to define the locations and sizes of the holes that will be drilled into the PCB. This layer is defined in the Gerber file using the .drl extension.

By defining these layers using the appropriate extensions in the Gerber file, the PCB manufacturer can use the information to produce a PCB that meets the required specifications. The Gerber format is a widely accepted standard for defining PCB layers and is used in many fabrication processes.

4 - Naming Conventions for Gerber Files

Naming conventions for Gerber files are important for the efficient and accurate manufacturing of PCBs. Gerber files refer to the image files used to instruct the PCB manufacturer on how to create the different layers and components of the board. To ensure that the files are interpreted correctly, it is critical to have consistent and clear naming conventions.

Traditionally, different file extensions are used to identify different layers and components. For example, “.GTL” is used to identify the “top copper” layer. “GBL” is used to identify the “bottom copper” layer. Similarly, “.GTS” is used to identify the “top solder mask” layer. “GBS” is used to identify the “bottom solder mask” layer.

In addition to using different extensions, it is recommended to adopt a consistent naming convention for the different components of the board. For instance, matching the names of components in the layout software with those used in the Gerber files can help streamline the manufacturing process. This can also prevent any confusion or errors that may arise during the manufacturing process.

It’s worth noting that naming conventions for Gerber files may vary slightly depending on the specific PCB design software used. Therefore, it is important to check with the software manufacturer or consult industry standards to ensure the naming convention is appropriate and widely understood.

5 - Common Formats and Versions of Gerber Files

There are several common formats of Gerber files, including Gerber X2, RS-274D, and RS-274X.

RS-274D is a legacy format that has been used for decades and is still supported by many PCB manufacturers. RS-274D consists of a series of commands describing the various PCB layers, such as drill sizes and positions, solder mask layers, and copper layer images.

RS-274X is an updated format that provides greater flexibility and ease of use than RS-274D. RS-274X includes new commands that allow for the description of more complex PCB features, such as embedded components and vias, and also adds support for additional layers of the PCB.

Gerber X2 is a newer format designed to address some of the shortcomings of the previous formats. Gerber X2 includes additional data, such as layer stack-up and component placement information, and is designed to be more compatible with modern software tools and manufacturing processes.

The differences and connections between these Gerber file formats can be somewhat complex, but generally speaking, RS-274D is the most basic format and is compatible with most PCB manufacturing processes. RS-274X adds additional features and capabilities, while Gerber X2 is the most advanced, including additional data and compatibility with modern software tools.

It’s important to note that while there are differences between these Gerber file formats, most PCB manufacturers can work with all of them. However, choosing the right format for your application and manufacturing process is still important to ensure the best possible results.

III. Generation of Gerber Files

Step 1 - Export Function of PCB Design Software

The first step in generating Gerber files is typically exporting the data from the PCB design software used to create the board layout. Most software packages include an export function specifically for creating Gerber files. This function exports information about each PCB layer in a format compatible with the Gerber file standard.

Step 2 - Preprocessing of Gerber Files

Once the Gerber files have been exported from the design software, they must be preprocessed to ensure they meet the specific requirements of the PCB manufacturer. This processing may include changes to the file format, resolution, or alignment of different layers. The preprocessing step ensures that the Gerber files are properly formatted for the subsequent manufacturing stages.

Step 3 - Compression and Verification of Gerber Files

The final stage of Gerber file generation involves compression and verification of the files. Files are typically compressed to make them easier and faster to transfer. Compression may also help reduce errors or inconsistencies that can arise during transfer. Verification of Gerber files ensures that all information is correct and complete and that the files adhere to the specific requirements of the PCB manufacturer. This verification step is critical in ensuring the PCB is properly manufactured to the desired specifications.

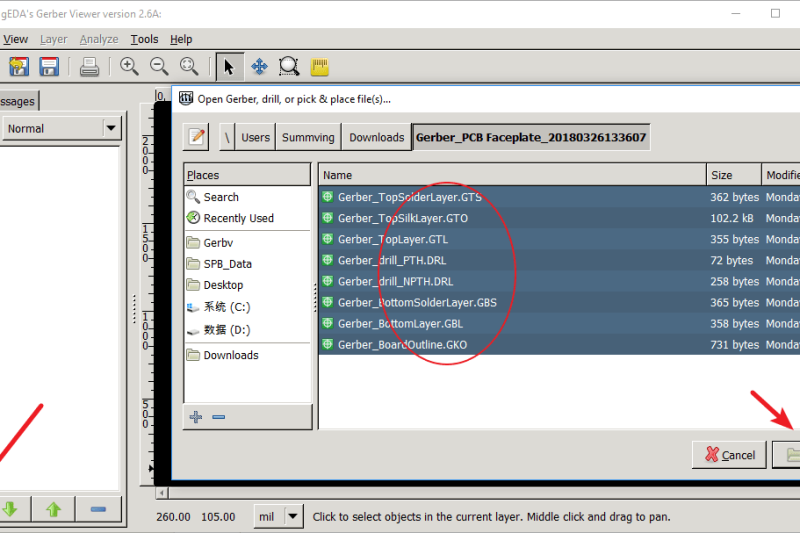

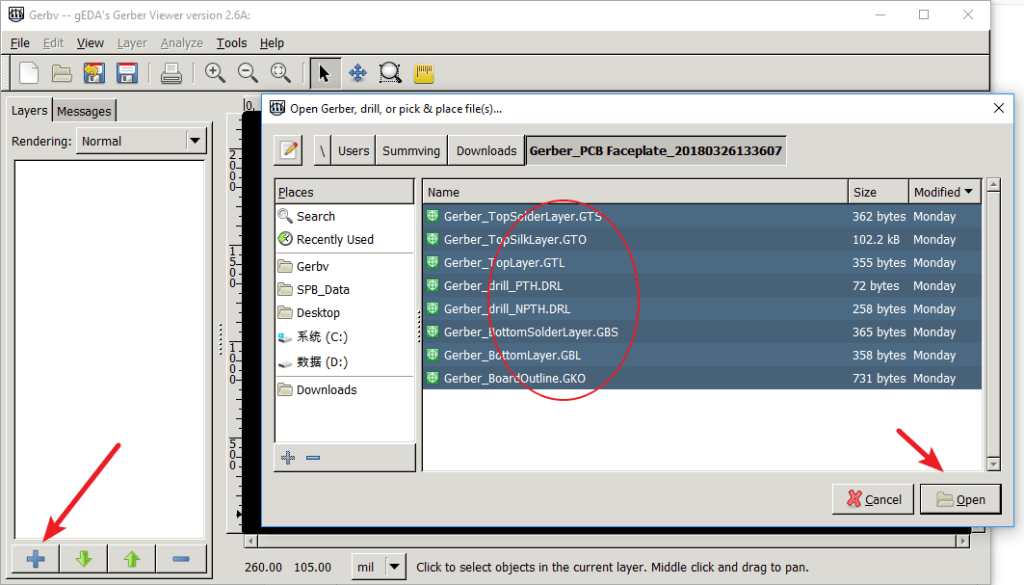

IV. Viewing Gerber Files

PCB Gerber files are graphic files that provide the necessary instructions for producing a PCB by describing layers, electrical connections, and other critical information. Gerber files can be generated using various software, such as circuit design tools, layout software, and CAM software. However, after generating Gerber files, it is crucial to view them to ensure their accuracy. Gerber viewers are software specifically designed to view Gerber files, inspect them, and help ensure the accurate manufacturing of the final PCB.

1 - Introduction to Gerber Viewers

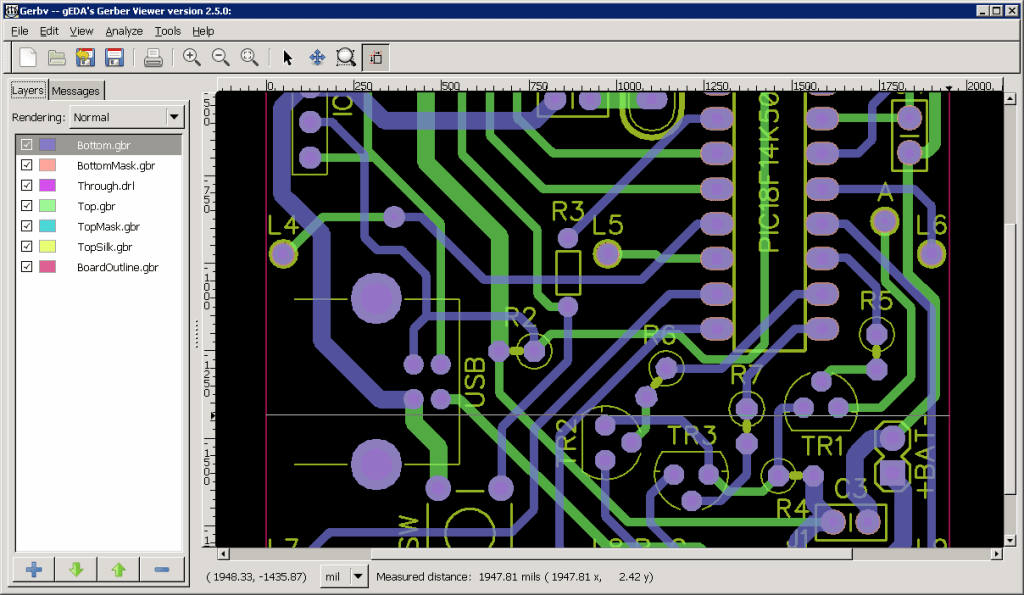

Gerber viewers are software tools for viewing and analyzing Gerber files, the industry-standard format for manufacturing PCBs. These files are generated from PCB design software and contain all the information needed to create the actual PCB.

Gerber viewers allow designers and manufacturers to view and analyze PCB designs before manufacturing. With a Gerber viewer, users can view the individual layers that make up the PCB, check for errors and inconsistencies, and verify that the design meets their requirements.

Gerber viewers are also useful for optimizing PCB designs. They allow designers to closely examine each layer of the PCB and identify areas where improvements can be made, such as reducing the number of vias or adjusting the placement of components.

Gerber viewers are an essential tool in the PCB design and manufacturing process. They help ensure the accuracy and quality of the final product and can save time and money by identifying design flaws early in the process.

2 - Functions of Gerber Viewers

Gerber viewers have a variety of functions that are critical to the design and manufacturing processes of PCBs. First, Gerber viewers allow PCB designers to inspect and validate the design before manufacturing begins. This includes checking for errors in the layout, such as overlapping traces or missing vias.

Gerber viewers also allow designers to generate and review multiple views of the PCB, such as top and bottom layers or drill holes, which can help identify potential issues. Additionally, they visualize the design in a 3D view, allowing designers to inspect the board from all angles.

Furthermore, Gerber viewers allow for comparing different design iterations and versions, which is crucial for ensuring that changes made to the design are consistent with the original specifications. This aids in detecting any discrepancies early on, allowing for prompt resolution.

Another important function of Gerber viewers is their ability to export the design into a format used to manufacture PCBs. They can generate the required fabrication data, such as Gerber, drill, or Excellon files. The generated files can be shared with manufacturers, PCB assembly service providers, or other relevant parties.

3 - 10 Recommended PCB Gerber Files Viewer

Sure, here are 10 PCB Gerber file viewers that are worth recommending, including Genesis 2000, CAM 350, and more:

1. Genesis 2000: A powerful PCB design software with a Gerber file viewer. It supports various Gerber file formats and provides a range of features for designing, verifying, and manufacturing PCBs.

2. CAM 350: A PCB design and analysis software with Gerber file viewing capabilities. It supports common Gerber file formats and provides advanced analysis tools for inspecting and verifying the PCB design.

3. GerbMagic: A simple but capable Gerber file viewer that supports common formats. It provides useful tools for inspecting and verifying the PCB design, such as zooming, measuring, and layer switching.

4. GC-Prevue: A free Gerber file viewer that supports various Gerber file formats, including RS-274D and RS-274X. It includes advanced features such as panelization and DFM checks and is compatible with multiple computer platforms.

5. DipTrace: A powerful PCB design software with a Gerber file viewer. It supports various Gerber file formats and provides various tools for designing, verifying, and manufacturing PCBs.

6. Pentalogix ViewMate Pro: A popular Gerber file viewer that supports Gerber, drill, ODB++, and IPC-2581 file formats. It includes advanced features such as JTAG, electrical testing, firmware import/export, and DFM checks.

7. Altium 365 Viewer: A cloud-based Gerber file viewer that supports various Gerber file formats and is accessible from anywhere with an internet connection. It offers seamless integration with other Altium software for enhanced collaboration and verification.

8. ZofzPCB: A lightweight but powerful Gerber file viewer that supports various formats and multiple-layer views. It includes fast rendering and deep layer control to optimize the PCB design and verify its accuracy.

9. GerberLogix: A feature-rich Gerber file viewer that supports various Gerber file formats and offers precise measurements and analyses of the PCB design. It includes advanced tools for panelization, database integration, and fabrication checks.

10. GC-PrevuX: A next-generation Gerber file viewer from GraphiCode that supports Gerber, drill, and ODB++ file formats. It includes real-time DFM feedback, schematic analysis, and solder paste optimization for efficient and accurate PCB design verification.

V. JHYPCB Offers Free Gerber File Review Services to Ensure High Quality PCB Manufacturing

At JHYPCB, we strive to deliver reliable and high-quality PCB manufacturing services to our customers. We understand that accurate Gerber files are crucial in producing quality PCBs, and therefore offer our clients free Gerber file review services.

To make the process as easy as possible for our clients, we recommend they put all their Gerber files and PCB manufacturing information into a folder and compress it into a zip file. They can email this to us at sales@pcbjhy.com, and our qualified engineers will review and validate the files for free.

Our commitment to quality extends beyond our Gerber file review services. We utilize the latest equipment and high-quality materials to manufacture PCBs that meet our rigorous standards. Our dedicated team of professionals works closely with clients to ensure their needs and expectations are met throughout the PCB production process.

At JHYPCB, we prioritize customer satisfaction and believe our customer-centric approach has been the key to our success. If you have any questions about our Gerber file review services or PCB manufacturing capabilities, please don’t hesitate to contact us at sales@pcbjhy.com. We look forward to hearing from you!

Related Reading

- PCB Design For Manufacturability Guide

- Guidelines For Optimal PCB Design For Assembly (DFA)

- Unlocking The World Of PCBs: Your Ultimate PCB Terms And Glossary Guide

- Bare PCB Technologies - Bare PCB Fabrication

- Effective Strategies for Creating and Managing BOMs in PCB Assembly

- PCB Manufacturing Process Guide

- What is BOM?