Flexible PCB Prototype Manufacturing Service

Flex PCB Prototyping

High Quality, Quick Turn Flex PCB Prototype manufacturing Service.

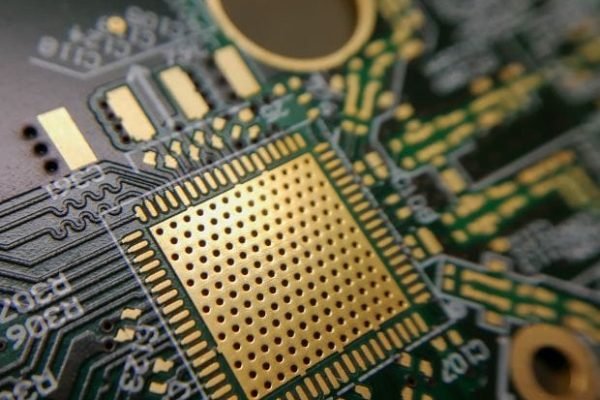

As a premier flex PCB manufacturer and PCB prototype manufacturer in China, JHYPCB specializes in providing fast and affordable flexible circuit board prototyping services to bring your product designs to reality. With over 10 years of experience in flex PCB fabrication, we understand the importance of flexible printed circuits for creating compact, lightweight electronic devices. Our flex PCB prototyping capabilities are focused on delivering high-quality flexible PCB prototypes with rapid turnaround times.

What is Flex PCB Prototype?

A flexible PCB prototype is a small-scale, early version of a flexible printed circuit board design that is created to test and refine the design before producing a final, full-scale version. Flexible PCBs are designed to be able to bend or twist, making them useful in applications where traditional rigid PCBs cannot be used, such as in wearable devices or other applications that require flexibility or compact size. Flexible PCB prototypes can be produced using various manufacturing techniques, such as etching, milling, or 3D printing, and are used to validate the design and ensure that it meets the desired specifications before proceeding with full-scale production.

Learn more about our PCB prototype manufacturing service.

The Importance of Flexible PCB Prototype

A flexible circuit board, also known as a flexible PCB, is a type of printed circuit board that is designed to be flexible and bendable. It is made up of a thin and flexible substrate material, such as polyimide, which allows it to be bent or folded into different shapes and configurations without breaking or damaging the circuitry. Flexible PCBs are commonly used in applications where space is limited and where the board needs to be able to conform to a specific shape or form factor, such as in wearable electronics or medical devices.

The importance of Flex PCB prototyping cannot be overstated. Prototyping allows engineers to quickly and inexpensively test new ideas and designs. This allows for iterative design and development, allowing engineers to make improvements to the design as needed. Prototyping also allows engineers to identify and correct any problems with the circuit before the final product is manufactured.

Flex PCB prototyping is particularly important for companies developing products for the wearable technology and medical device markets. These industries require compact, highly-mobile electronics that can withstand harsh environments. Flex PCBs are ideal for these applications because they are flexible, durable, and resistant to environmental factors.

Flexible PCB Prototype Services

Your go-to Flexible PCB Prototype Manufacturer

A flexible PCB prototyping allows engineers to quickly and inexpensively test new designs, identify and correct any problems, and ultimately produce high-quality products.

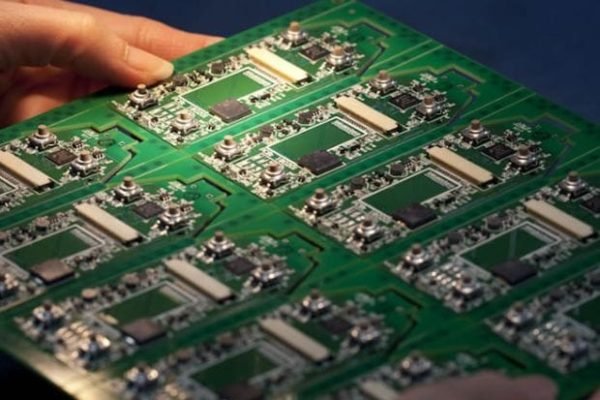

We know the importance of flexible PCB prototype for the success of your project. JHYPCB has the advanced equipment and experienced engineers required to build highly reliable flexible printed circuit boards for various applications. We can manufacture single-sided, double-sided, and multilayer flexible PCB prototypes using most substrates and our advanced manufacturing processes. We are also able to provide you with flexible PCB assembly services. We are your first choice for all your circuit board development needs from prototype to full production.

01

Flexible PCB Manufacturing Service

- Flexible PCB Prototype

- Single Layer Flexible PCB

- Double Sided Flexible PCB

- Multilayer Flexible PCB

- Rigid-Flex PCB

- High Volume Flexible PCB Production

- Flexible PCB Assembly

02

Markets served

- Medical devices

- Automotive components

- Wearable devices

- Robotics

- Military and aerospace applications

- Consumer electronics

- Telecommunications

Quality Assurance

Professional Team

Competitive Prices

On-Time Delivery

Excellent Service

Benefits of JHYPCB's Flex PCB Prototypes

JHYPCB offers a number of advantages that make us the right choice for your flex PCB prototype needs:

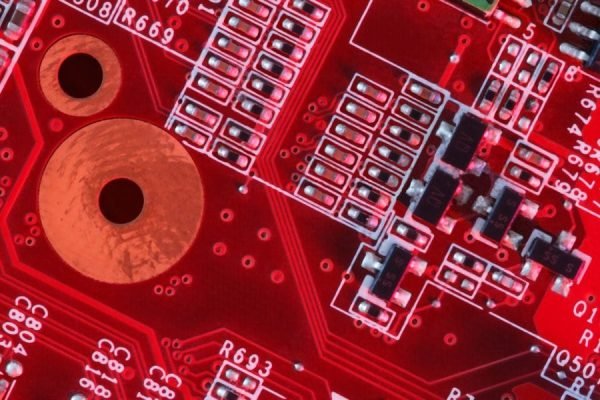

- Affordable Pricing – Our flex PCB prototypes are very competitively priced. Get instant quotes online and order as low as 1-2 piece prototypes without high costs.

- High Mix Support – We specialize in supporting high mix, low volume orders for prototypes and small batch production with no minimum order quantities.

- Fast Turnaround – With our streamlined processes, you get your simple flex PCB prototypes in as fast as 24 hours by just uploading your files.

- Quality Assurance – Strict quality control and testing ensure your flex PCB prototype matches your design perfectly.

- One-Stop Service – We offer integrated PCB design, fabrication, component sourcing, and assembly services to simplify prototyping.

- Dedicated Support – Our engineering team provides guidance to optimize designs for manufacturing and resolve any technical queries.

- Production Scalability – We can seamlessly scale up production once your prototype is validated, with global manufacturing facilities.

With these advantages, JHYPCB is the ideal partner for cost-effective, fast, and tailored flexible PCB prototyping solutions to meet your specific requirements.

JHYPCB is committed to providing convenient, fast, and affordable flex PCB prototyping services to enable efficient design verification, avoid costly errors, and speed up time-to-market. Whether you need 1-2 piece prototypes or larger quantities, we offer customized high-quality solutions tailored to your needs. Order with confidence.

03

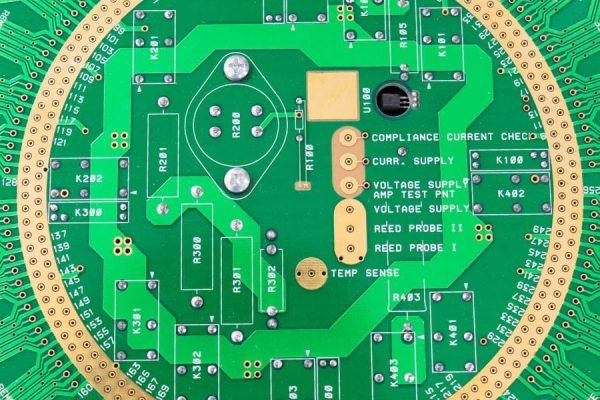

Highlighted Manufacturing Capabilities.

As a leading flexible PCB manufacturer and supplier, we offer from flex PCB prototypes to mass production services; we have advanced flexible circuits and rigid-flex PCB manufacturing processes and capabilities. As your go-to flexible PCB prototype manufacturer, you can manufacture flex circuit boards with smaller line trace spaces and micro-vias. Please consult with our flexible circuit expert and engineering services team to help you determine what the optimal technologies are for your project’s application. We also offer extremely fast and quick-turn flex PCB prototyping services.

| Specifications | Capabilities |

|---|---|

| Layers | 1-16 Layers |

| Order Quantity | No Minimum Order Quantity. |

| Polyimide Base Material | Polyimide Flex, PET (Transparent) |

| Finished Board Thickness | 0.5mm~3.0mm (0.02″~0.12″) |

| Minimum Hole Size | 4mil |

| Solder Mask | Green, White, Blue, Black, Red, Yellow |

| Coverlay | PI and PET film |

| Stiffener | FR4/PI/PET/SUS/PSA |

| E-test | 100% |

| Max Finished Size | 250*1000mm |

04

Prototype to Production Quantity

At JHYPCB, we offer high-quality flexible PCB prototype service to suit your custom requirements. In addition, we offer quick turn flex PCB Prototype services that makes go-to-market that much easier. A large portfolio of satisfied clients stands testimony to our prototype to full production run manufacturing capacity and our technical and engineering capabilities. Our state-of-the-art equipment and superior technical expertise ensure that your mass production is smoothly completed. You can easily test and ratify your product’s functional design. In addition, our PCB prototypes help reduce the overall project cost as any issues are found in the early stages of the cycle.

Our prototype-to-production manufacturing capacity makes us different; our technical, engineering, procurement, and customer services give us a competitive advantage.

We also provide one-stop services from the flexible circuit and rigid-flex PCB prototype assembly to mass production that reduce your vendor count, production delays, and quality issues. Let us do your component sourcing, flexible PCB manufacturing, assembly, and testing from a single component to complicated box builds.

05

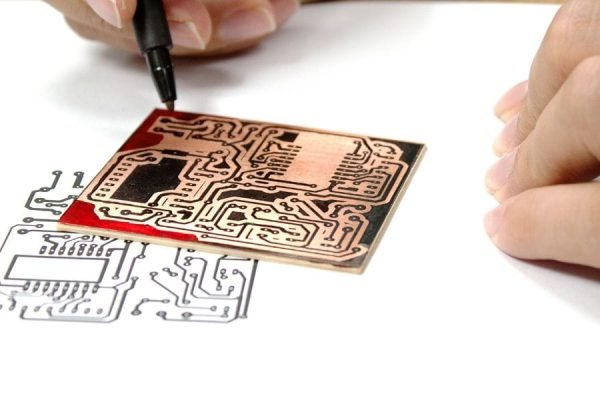

Flex PCB Prototype Process

JHYPCB has an efficient process to deliver high-quality flex PCB prototypes quickly:

- Submit Your Order Online – Just upload your Gerber files here.

- Design Review – Our engineers review your design and offer recommendations if any optimizations are needed for manufacturing or reliability.

- Fabrication – We use advanced equipment to precisely fabricate your designed flex PCB. This includes photolithography, etching, lamination of flexible substrates, drilling, etc.

- Testing – Each flex PCB is rigorously tested for continuity, dimensions, flexibility, electrical performance and other parameters. We ensure it meets IPC standards.

- Delivery – The flex PCB prototypes are shipped via DHL/FedEx express courier to reach you quickly and reliably.

- Post-Delivery Support – Our technical support team is available to answer any questions and provide design assistance even after delivery.

With years of experience, we have perfected this streamlined process to deliver high-quality flex PCB prototypes tailored to your requirements in the shortest turnaround times.

Is your Flex PCB Prototype Ready for Fabrication?

At JHYPCB, we create every printed circuit board and flexible PCB prototype or mass production to our customer’s custom specifications. We manufacture the flexible PCB prototype you need; our team of experienced engineers will review your PCB requirements to ensure no issues during Manufacturing.

You can send us your flexible PCB data files, and we will run a complete DFM check for manufacturability. Experience how our engineering support gives customers the most in-depth feedback, eliminating delays and discovering any quality problems before PCB fabrication.

FAQs

Frequently Asked Questions

Can you offer multilayer flexible PCB prototype service?

Yes, certainly. Send your Gerber files and custom requirements with us and see them come to life.

Can you offer quick turnaround time for flexible PCB prototyping?

Yes. We offer quick turn flex PCB prototyping that expedites your go-to-market plans.

Do you offer low-cost flexible PCB prototyping service?

Don't worry; our prices for flex PCB prototyping are extremely cost-effective.

Do you have a minimum order quantity requirement?

Not at all. You can rely on us for prototype quantities and your full production runs.

What surface finish options can you offer for flex PCB prototyping?

Yes, we offer multiple surface finish options, depending on the final environment in which the flex PCB prototyping has to operate and your requirement.

How to get a quick quote for flex PCB prototype from JHYPCB?

You could get a quick quote online by submitting your custom requirements. All you need to do is fill out this flex PCB prototyping quote form. You could also write to us at sales@pcbjhy.com for any clarifications. We will be happy to hear from you and offer custom solutions.