Getting a fast prototype made is critical when designing any new PCB. You want to be able to validate your design and catch errors early in the development process before finalizing mass production. For that, you need a quick turnaround on high-quality prototype boards. Choosing the right rapid PCB prototyping partner is key. Look for manufacturers that specialize in providing fast PCB prototype services and can deliver in 5-7 days or less. This quick turnaround time allows you to test your design, make modifications, and reiterate quickly. Companies in China are a good option as many PCB manufacturers there offer quick turnaround times for basic board fabrication. Just be sure to do your research to find a reliable, high-quality manufacturer for your fast PCB prototyping needs. The goal is to find a manufacturer that can deliver quality boards with quick turnarounds so you can get to test your design as soon as possible.

Table of Contents

Why Fast PCB Prototyping Matters

A fast PCB prototype is critical to the success of your electronic device manufacturing business. It allows you to quickly identify any design errors or functionality issues before proceeding to the final product. In addition, a fast PCB prototype helps you to save time and money in the long run.

One of the benefits of a fast PCB prototype is that it provides a quick turnaround time. You can get a prototype made in a short amount of time, which means that you can move on to the next phase of the design process more quickly. This can help you to beat your competitors to market and gain an advantage in the industry.

Another benefit of a fast PCB prototype is cost savings. When you have a prototype made quickly, you can identify any design issues or flaws in the functionality of the device. This allows you to make changes and improvements to the design before the final product is manufactured. Fixing issues at the prototype stage is much less expensive than having to recall or fix a final product.

Selecting the Right PCB Prototype Manufacturer

Choosing the ideal partner for rapid PCB prototyping is critical. Consider these factors:

- Specialization in fast turnaround services

- Proven track record of quality and reliability

- Advanced manufacturing capabilities

- Positive customer reviews and testimonials

- Clear communication channels

Pro Tip: Many Chinese PCB manufacturers, like JHYPCB, offer excellent quick-turn services. Ensure you thoroughly vet potential partners to find the right balance of speed, quality, and cost.

Optimizing Your PCB Design for Quick Turnaround

Once you’ve chosen your manufacturer for rapid prototyping, you need to optimize your design files to facilitate the quick fabrication of your PCB prototypes. Keep the circuit as simple as possible for your initial prototype. Only include the most essential components and features to test the core functionality. You can add to the complexity later after validating the fundamental design. Use a clear, descriptive naming convention for all your signals and components in the schematic. This will help avoid confusion during layout. Provide the manufacturer with complete Gerber files including layers for copper, solder mask, silkscreen, etc. Double check that all required files are present and error-free. The manufacturer can’t expedite fabrication if they have to come back to you with questions, corrections, or requests for additional files. You want your design files to be 100% complete and accurate to enable the fastest possible turnaround time. Carefully preparing your design files is a key step for ensuring the quick delivery of quality PCB prototypes. Take the time upfront to optimize your design and provide everything needed to your manufacturer.

Effective Communication Strategies

Communication and coordination with your PCB prototype manufacturer are crucial for an expedited turnaround. Make sure to align the expected timeframe and production schedule upfront. Confirm they have all the information needed to meet your requested delivery date. Provide them with your complete contact information so they can get in touch easily if any issues arise. Be responsive to any inquiries from the manufacturer and provide clarification or additional details quickly to avoid potential delays. Once production is underway, check in periodically for updates on the status. However, avoid excessive pinging as that can actually slow things down on their end. Always be courteous in interactions. Expect that rush orders may cost more and plan your budget accordingly. If the manufacturer indicates they cannot meet your needs, it’s better to know as soon as possible. Effective communication establishes reasonable expectations, coordinates production, and sets you up for an optimized prototype delivery timeframe. Keep an open channel with your manufacturer and promptly address any requests or issues they may have.

Expedited Shipping Options

When your PCB prototypes are ready, don’t let slow shipping delay your ability to test them. Coordinate shipping details with your manufacturer ahead of time. Often, you can pay a bit extra to expedite the delivery of your boards once fabrication is complete. Options like DHL, FedEx, or UPS express shipping can significantly decrease transit time compared to standard methods. However, express shipping can cost more depending on location, weight, and other factors. Make sure to get an accurate estimate from your manufacturer on your options and the costs. Then decide if the faster transit time is worth the premium shipping rates. If budget is a major factor, you may opt for standard ground shipping to reduce costs, but this will increase the total turnaround time. In any case, make sure to provide the manufacturer with a detailed, accurate shipping address and point of contact. Confirm all logistics to ensure your packaged prototypes arrive safely and on schedule via your preferred shipping method.

Thorough Testing of Your Fast PCB Prototype

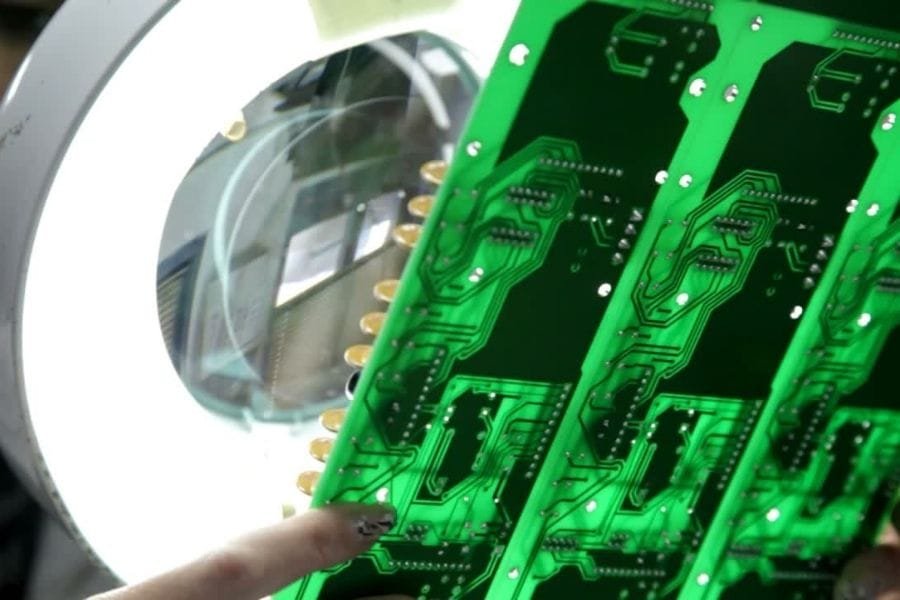

Once your rapid prototyped PCBs arrive, don’t just assume everything is perfect based on a quick visual inspection. You need to thoroughly test the boards to validate your design before moving to mass production. Carefully examine the boards under magnification to check for any manufacturing defects or errors. Review the PCB layout and silkscreen markings to ensure accuracy. Test critical components like connectors and interfaces to make sure they are right. Verify any programmed firmware meets specifications and performs as expected. Comprehensively check board functionality by putting it through a range of operating conditions and use cases. Be meticulous in testing – you want to catch any issues now in the prototypes rather than after you’ve started mass production. Document any defects, performance problems, or design changes needed. Share feedback with your manufacturer to improve quality. Refine your design files and order another prototype iteration if needed. While thorough testing requires time and effort, it’s essential to catch problems early and ensure your PCB design is ready for volume manufacturing.

7 Pro Tips to Accelerate Your PCB Prototype Process

- Plan meticulously before ordering

- Choose the most suitable manufacturing method

- Consider design size and complexity

- Optimize PCB layout for efficiency

- Utilize simulation software for pre-manufacturing testing

- Build a relationship with your chosen manufacturer

- Consider parallel prototyping for complex designs

5 Common Pitfalls to Avoid in Fast PCB Prototyping

There are several common mistakes that you should avoid when getting a fast PCB prototype:

Neglecting to plan ahead: Failing to plan ahead can lead to delays in the PCB prototype process. Make sure to have all the necessary materials and components ready to go before submitting your order.

Choosing an unreliable manufacturer: Choosing an unreliable manufacturer can result in poor quality PCB prototypes, delays, and increased costs. Do your research and choose a reputable manufacturer.

Not double-checking the design: Failing to double-check the design can lead to errors and delays in the PCB prototype process. Take the time to review and double-check your design before submitting it for manufacturing.

Overcomplicating the design: Overcomplicating the design can lead to delays and increased costs. Keep your design simple and focused on the necessary functionality.

Ignoring test results: Ignoring test results can lead to issues with the final product. Make sure to address any issues or flaws identified in the prototype testing phase before moving on to manufacturing the final product.

Why Choose JHYPCB for Your Fast PCB Prototype Needs

If you’re looking for a reliable and efficient PCB prototype manufacturing service, look no further than our company. With years of experience and a commitment to quality and customer satisfaction, we can help you get the fast PCB prototypes you need to take your business to the next level.

In addition to our fast PCB prototype manufacturing service, we also offer a wide range of other PCB manufacturing and assembly services, including high-volume production runs and turnkey solutions. We use the latest technology and equipment to ensure that every PCB we produce is of the highest quality and meets your exact specifications.

At our company, we pride ourselves on our commitment to customer service and satisfaction. We work closely with our clients to ensure that we understand their needs and deliver results that exceed their expectations. From start to finish, we’ll be there to answer your questions, address your concerns, and provide you with the best possible service.

So if you’re in need of fast PCB prototype manufacturing, or any other PCB manufacturing or assembly service, look no further than our company. Contact us today to learn more about how we can help you take your business to the next level. We look forward to working with you!

Conclusion

In conclusion, a fast PCB prototype is essential to the success of your electronic device manufacturing business. By following the strategies and tips outlined in this article, you can speed up the PCB prototype process, avoid common mistakes, and save time and money in the long run. Remember to choose a reputable manufacturer, double-check your design, simplify your design, and plan ahead to ensure that you get a high-quality PCB prototype quickly and efficiently.

Overall, getting a fast PCB prototype requires a combination of careful planning, effective strategies, and attention to detail. By taking the time to properly prepare and work with a reputable manufacturer, you can ensure that you get a high-quality PCB prototype quickly and efficiently, allowing you to move on to the next phase of the manufacturing process with confidence.

FAQs

With specialized services, you can expect turnaround times of 5-7 days or even less.

While expedited services may cost more upfront, they often lead to overall project savings by catching issues early.

Yes, but simplifying initial prototypes to core functionality can speed up the process.

It's crucial. The right manufacturer can significantly impact both speed and quality.

Thorough planning, design optimization, and complete, error-free files are key to rapid turnaround.

Related Reading:

- Speed Up Your PCB Design with Double Sided Prototyping

- Affordable PCB Prototyping: Options Worldwide

- Get Your PCB Prototypes Rapidly with Our Fast Turn Services

- How Much Does a PCB Prototype Cost? Pricing Guide for 2024

- What is PCB Prototype? The Ultimate Guide

- The Advantages of Double-Sided PCBs for Prototyping

- How to Find the Best Cheap PCB Prototype Supplier – Key Criteria