Single Layer PCB Manufacturer

Single Layer PCB: A Comprehensive Guide

A single-layer PCB, also known as a single-sided PCB, is a printed circuit board with only one layer of conductive materials. JHYPCB is a professional single-sided PCB manufacturer that offers high-quality, quick-turn single-layer PCB fabrication service.

Welcome to JHYPCB, your premier source for high-quality single-sided and single-layer PCBs in China. With over 10 years of experience manufacturing PCBs, JHYPCB specializes in producing top-notch single-sided and single-layer boards for clients worldwide.

Our single-sided PCBs feature copper traces on only one side of the board, while our single-layer PCBs have copper traces throughout a single layer. Both provide a cost-effective solution for simple circuit designs and prototyping needs.

At JHYPCB, we utilize cutting-edge facilities and equipment to fabricate single-sided and single-layer PCBs to your exact specifications. Our rigorous quality control standards ensure your boards are expertly crafted and thoroughly tested.

Whether you need quick-turn prototypes or medium-sized production runs, JHYPCB has the capabilities to deliver high-quality single-sided and single-layer PCBs on time and on budget. We offer competitive pricing with no hidden fees.

Contact us today to learn more about our single-sided and single-layer PCB fabrication services. Our team of engineers is ready to answer any questions and help you get your project started on the right track.

Table of Contents

Add a header to begin generating the table of contents

What are Single Sided or Single Layer PCBs?

Single-sided or single-layer printed circuit boards provide an affordable solution for basic circuit and prototype designs.

A single-sided PCB has copper traces on only one side of the board. Components are mounted on the same side as the copper traces. Single-sided PCBs work well for simple layouts with minimal component placement needs. They allow traces to run uninterrupted without the need for drilling or plating through holes.

A single-layer PCB has copper traces throughout the entire area of one board layer. While physically a double-sided board, electrically it functions as a single-layer board because traces exist on one signal layer only. Single layer boards accommodate more complex tracing while still being cost-effective for moderate complexity designs.

The main advantages of single-sided and single-layer PCBs include:

- Lower Cost – They require fewer layers and manufacturing steps compared to multilayer boards. This results in very economical pricing per unit.

- Faster Lead Times – With fewer fabrication steps, single-sided and single-layer PCBs can be produced very quickly. Lead times range from 24 hours for prototyping to 5 days for production.

- Ease of Modification – It’s simple to make trace pattern changes on one or two layer boards. This facilitates engineering design iterations.

- Lighter Weight – Having fewer layers results in a thinner and lighter board weight. This helps reduce product size and cost.

Single-sided and single-layer PCBs meet the needs of many hobby, academic, and commercial electronic projects. Their simplicity, cost-effectiveness, and quick turnaround times make them an attractive option for creating a functioning circuit board.

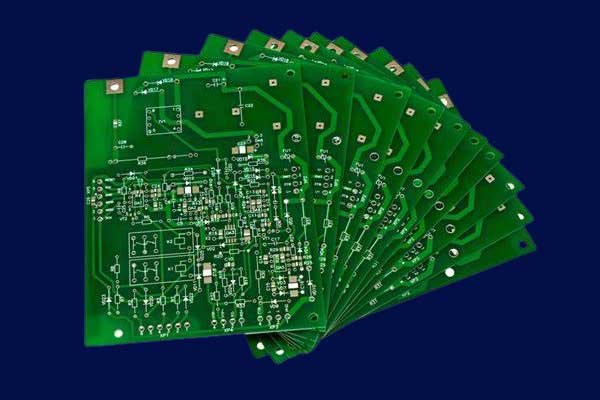

A bare single-sided PCB sample with a green solder mask

JHYPCB's Advantages in Single Sided and Single Layer PCB Manufacturing

With over 10 years of experience manufacturing printed circuit boards, JHYPCB has honed our process to deliver exceptional quality single-sided and single-layer PCBs. We utilize cutting-edge facilities equipped with the latest fabrication and assembly technologies to produce boards that meet and exceed our customers’ expectations.

Our factory employs advanced PCB equipment from industry leaders like Orbotech and Atg. This enables us to create precision boards with fine line traces and spacing down to 3 mil, wrap-around plating, and other demanding fabrication requirements.

We follow strict quality control standards at every stage of production. From incoming raw material inspection to solder mask cure verification, we carefully examine PCBs to ensure consistent quality. We can reliably produce boards from run to run with the highest degree of repeatability.

For every order, we collaborate closely with customers to understand their design needs and specifications. Our engineers provide knowledgeable guidance to optimize the board layout for manufacturability and performance. Once the design is finalized, we fabricate the PCBs according to the customer’s exact specifications.

In addition to prototyping services, JHYPCB has the volume production capacity to handle orders ranging from a few boards up to 10,000 boards. We can accommodate small prototype orders within 24 hours as well as medium-sized production runs, with standard lead times of 5 days for production.

Our pricing is highly competitive, with no hidden fees. As a full-service PCB solutions provider, JHYPCB delivers exceptional quality single-sided and single-layer boards with responsive customer service, expert technical assistance, and transparency in pricing. Contact us today to experience the JHYPCB difference!

What is the Single-Sided PCB Stackup?

The single-sided PCB stackup refers to the arrangement of layers in a single-sided PCB. It typically consists of three layers:

The substrate layer, which is the base material of the PCB.

The conductive layer, which is the layer that contains the conductive pathways.

The protective layer, which is the top layer that protects the conductive pathways from environmental damage.

Read More: PCB Layers Explained: Multilayer PCB Stakcup

What are the Single Layer PCB Types?

Here are the main types of single layer PCBs:

- Single-sided PCBs – These have copper traces on only one side of the board. Components mount on the same side. Best for simple circuits.

- Double-sided, single-layer PCBs – These are constructed as double-sided boards but with copper only on the top or bottom layer. Provides more surface area than single-sided.

- PTH single layer PCBs – Plated through-hole (PTH) construction allows connections between the top and bottom layers. Good for moderate complexity.

- Non-PTH single-layer PCBs – Uses plain through holes with no plating. Most cost-effective option but has no top/bottom interconnections.

- Flexible single-layer PCBs – These use a flexible base material like polyimide. Enables bending and folding applications.

- Rigid-flex single-layer PCBs – Combines standard rigid PCB sections with flexible circuits in between. Allows dynamic movement.

- Metal-backed PCBs – A metal substrate is used as the board base for better heat dissipation. Used in high-power circuits.

- FR-4 single-layer PCBs – The most common glass-reinforced epoxy laminate substrate used for consumer PCBs. Cost-effective option.

- High-frequency single layer – Uses substrates like Rogers or Taconic for better performance up to microwave frequencies.

- High-density interconnect (HDI) – Extremely tight trace spacing and small vias. Used for highly miniaturized designs.

So in summary, there are several construction methods and substrate materials to choose from when designing a single layer PCB depending on the design requirements and constraints.

What are the Disadvantages of Single Layer PCB?

Here are some potential disadvantages of using a single layer PCB design:

- Limited circuit complexity – The lack of multiple layers restricts component density and routing options for more complex circuit designs.

- No internal power or ground planes – Without a continuous internal ground plane, issues with noise pickup and interference may arise.

- Lower component density – Component placement can be more spread out, resulting in larger overall board sizes.

- Limited thermal capabilities – Heat dissipation is restricted without thermal vias and internal power planes to distribute heat.

- Less durable – Single layer boards are more flexible and prone to bending stress compared to multilayer boards.

- Difficult impedance control – Controlling trace impedance and matched lengths is challenging with no reference ground plane.

- No shielding – Sensitive circuits or RF sections lack shielding from other board sections without multiple layers.

- Lower speeds – High frequency traces and components placement is restricted due to less optimized layer usage.

- Limited routing channels – With only one layer for signals, complex routing with traces spanning the entire board may be needed.

- No buried vias – Vias cannot be used to transition between internal layers since there are none.

While disadvantages exist, single layer boards provide a simple and low-cost solution when the circuit complexity and performance requirements are relatively basic. For more advanced designs, multilayer boards are likely needed.

How to Design a Single-Layer PCB?

Here are some tips for designing an effective single-layer PCB:

- Plan component placement first. Position components to minimize track lengths and allow critical traces to run uninterrupted.

- Use surface mount devices (SMD) instead of through-hole parts when possible. This conserves routing space on the single layer.

- Route power and ground tracks first as wide traces along the edges or around the board. This provides a partial ground plane.

- Use vias sparingly as they consume routing space on the single layer. Minimize via counts through creative routing.

- Route tracks orthogonally using 45 or 90 degree angles when possible. Avoid acute angles that waste space.

- Use autorouters and design rule checks to assist with trace routing and catch any errors.

- Clearly designate inputs, outputs, power connections, and other interfaces with labels.

- Partition the PCB layout into sections for analog and digital circuits to prevent noise interference.

- Add generous clearance between traces and pads. Allow extra spacing for high voltage traces.

- Include test points for debugging and validation. Mark these clearly on the silkscreen layer.

- Simulate the PCB to verify proper functionality and routing before manufacturing.

With careful planning and optimization, it is possible to successfully implement many design circuits using a simple single-layer PCB layout. Prototyping on single-layer boards can help verify a design before moving to multilayer.

What is the Single Layer PCB Raw Materials?

Single-layer PCBs are typically made from a combination of different materials, including:

- Substrate material: The substrate material is the base material of the PCB and is usually made of fiberglass or composite materials such as epoxy resin and glass fibers.

Conductive material: The conductive material is typically made of copper and is used to create the conductive pathways on the PCB.

Protective material: The protective material is used to cover the conductive pathways and protect them from environmental damage. This material is usually a resin or lacquer.

Read More: Complete Guide for PCB Material

What are the Applications of Single-Sided PCB?

Here are some of the common applications for single-sided PCBs:

- Simple electronic devices – Single-sided PCBs are commonly used in simple electronic devices like alarms, timers, sensors, detector circuits, etc. where the circuit complexity is low.

- Prototyping – Engineers often prototype circuits on single-sided PCBs as they are inexpensive and allow quick design modifications.

- Education/DIY projects – Single-sided boards are widely used for creating hobby electronics, school projects, and DIY tech due to their ease of use.

- Low-cost consumer electronics – Products like simple toys, portable radios, flashlights, etc. often use single-sided PCBs to reduce cost.

- Testing new designs – Engineers use single-sided boards to test out new circuit ideas before moving to more complex PCB implementations.

- Low-frequency analog circuits – Simple analog circuits involving amplification, filters, and oscillators can be efficiently implemented on single-sided boards.

- Control panels – Many equipment control panels and instrument displays use single-sided PCBs for mounting switches, indicators, and displays.

- RF/Antenna circuits – In certain high-frequency circuits like crystal oscillators, simple antennas can be designed on single-layer boards.

- Power supplies – Linear and switch-mode power supplies generating low to moderate power output can utilize single-sided PCB layouts.

So in summary, single-sided PCBs are the most cost-effective choice for any non-complex low-frequency electronics device or design. Their simple construction makes them ideal for fast prototyping iterations.

How Are Single-Sided PCB Manufacturing?

Single-sided PCBs are manufactured using a photolithography process, which involves the following steps:

Preparing the substrate: The substrate material is cut to size and cleaned to remove any contaminants.

Depositing the conductive material: The conductive material is deposited onto the substrate using a deposition process, such as electroplating.

Patterning the conductive material: The conductive material is patterned using photolithography techniques to create the conductive pathways.

Applying the protective material: The protective material is applied over the conductive pathways to protect them from environmental damage.

JHYPCB's PCB Solutions

At JHYPCB, we provide a comprehensive range of printed circuit board solutions beyond just single-sided and single-layer boards. We have extensive experience in manufacturing:

- Double-Sided PCBs – These have copper on both sides of the board with components mounted on one or both sides. Double sided boards allow for more complicated tracing with the addition of vertical interconnects between layers.

- Multilayer PCBs – With four or more layers, these boards enable very complex circuit designs by stacking and interconnecting multiple thin PCB layers. Multilayer boards are ideal for sophisticated electronics requiring miniaturization.

- Rigid-Flex PCBs – Combining rigid board sections and flexible circuits together, rigid-flex PCBs provide dynamic mechanical performance for bending and folding applications.

- HDI PCBs – With trace spacing/width down to 2 mils, high-density interconnect (HDI) PCBs accommodate ultra-dense circuit packing and miniaturization needs. HDI technology facilitates advanced consumer electronics.

- Metal Core PCBs – With an aluminum or copper core for enhanced thermal heat dissipation, metal core PCBs enable high-power electronics and LED circuit designs.

We support the most demanding PCB design requirements, including high layer counts, blind and buried vias, controlled impedance, and heavy copper boards. Our engineering team has extensive experience across a wide range of end products – from telecommunications boards to auto electronics to industrial control systems.

Whether you need just a few prototype boards or full-scale mass production, we deliver. Our quick-turn prototyping services enable 1-day turnaround for 10 boards. The production runs from small batches of 10 boards to larger quantities of 10,000+ boards are easily accommodated.

With JHYPCB as your trusted PCB solutions partner, you have a one-stop resource to bring your designs from concept to high-volume manufacturing.

FAQs

What is the Single Layer PCB Cost?

The cost of single-layer PCBs varies depending on several factors, including the size of the PCB, the number of components, and the materials used. However, single-layer PCBs are typically cheaper than multi-layer PCBs, making them a more cost-effective option for low-complexity electronic devices.

What is the difference between Single Layer and Double Sided PCB?

The main difference between single-layer and double-sided PCBs is that single-layer PCBs have conductive pathways on one side of the board only, while double-sided PCBs have conductive pathways on both sides of the board. Double-sided PCBs are more complex and offer more functionality than single-layer PCBs.

What is the difference between Single-layer and Multilayer PCB?

Single-layer PCBs have conductive pathways on one side of the board only, while multilayer PCBs have conductive pathways on multiple layers within the board. Multilayer PCBs are more complex and offer more functionality than single-layer PCBs.

What are the common substrate finishes?

HASL, immersion silver, ENIG, and immersion tin are popular finish options.

What are recommended PCB materials and thicknesses?

FR-4 with 1oz (35 μm) copper is standard. Flex PCBs use polyimide. 1.6mm thickness is common.